SRS Crisafulli Explores Dredging and Hydropower

Energy production and consumption worldwide is influenced by many factors. Resource availability, economic activity, population growth and...

1 min read

Elizabeth Kaiser : Wed, May 16, 2012 @ 08:05 AM

Whether you have just installed your new dredge or you have been dredging for a while, you should follow a lubrication and maintenance schedule in order to ensure a long and useful life for your dredge. SRS Crisafulli includes a suggested maintenance schedule in our dredge Operations and Maintenance (O&M) manuals.

The following suggested maintenance schedule is included in all SRS Crisafulli dredge Operations and Maintenance (O&M) manuals.

LUBRICATION & MAINTENANCE SCHEDULE (ROTOMITE):

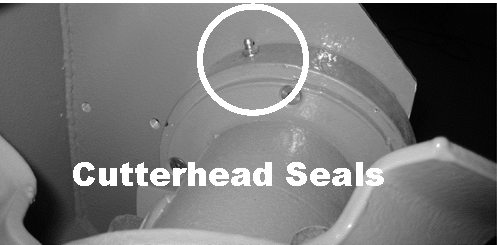

DAILY:| Lubrication Points on a Rotomite |

|

|

|

WEEKLY:

EVERY 100 HOURS:

EVERY 250 HOURS:

EVERY 500 HOURS:

EVERY 1000 HOURS:

Watch new video! SRS Crisafulli's Rotomite 6000C Series.

Watch how to install discharge tubing.

Download a Dredge Application form.

Calculate cost of replacement parts.

Energy production and consumption worldwide is influenced by many factors. Resource availability, economic activity, population growth and...

Submitted by Dave Stoltenberg, Dredge Rental Specialist, SRS Crisafulli

By Eric Lillberg, SRS Crisafulli Senior Applications Engineer When I first started as an applications engineer for SRS Crisafulli, I searched for...