Suggested Tips: Dredge Maintenance Schedule

Whether you have just installed your new dredge or you have been dredging for a while, you should follow a lubrication and maintenance schedule in...

2 min read

Elizabeth Kaiser : Wed, Nov 30, 2011 @ 08:11 AM

We have all been there. You are right in the middle of a project and something goes out. Of course it’s going to happen in the middle of your project – parts don’t usually go out while they are just sitting there idle. So the age-old question is does it pay to stock those critical replacement parts?

In my 15 years in the sales industry, I can remember countless times when I had to overnight parts to contractors or customers who were in the middle of a project and who needed a critical replacement part that had put a stop to all production. In the best case, the part is in stock and can be sent overnight. Let’s not talk about the production parts that take a week to manufacture, or the part that is on backorder and will take 7-10 days to arrive.

In the dredging industry what is the actual cost of not having those critical spare parts? The following are just averages but you can plug in your own numbers.

Let’s use an impeller for example:

Cost with having spare part on hand

Initial Cost of Impeller - $1,500.00

Downtime replacing part – 3 hours

Cost of downtime (lost wages) – 3 hours x $200.00 per hour = $600.00

Shipping Charge - $50.00

Total = $2,150.00

Cost of not having spare part

Impeller Cost - $1,500.00

Downtime, 7 days manufacturing time + 2 days shipping – 9 days x 8 hours per day = 72 hours

Cost of downtime (lost wages) - 72 hours x $200.00 per hour = $14,400.00

Next day Shipping Charge - $500.00

Total = $16,400.00

Use this calculator and try it for yourself.

It is an understatement to say that keeping critical spare parts on hand is imperative. When you look at factors such as unpredictable demand, time tracking the part down, product availability, as well as the downtime waiting for the part, I would say stocking critical spare parts is a key business decision that will save you a lot of money in the long run.

We do have spare wheels but this one is for another customer. I can expedite one for you, have it ready in about 6 months!

We do have spare wheels but this one is for another customer. I can expedite one for you, have it ready in about 6 months!

Now there are a couple of questions that you have to ask:

To answer question number one, you should consider the working parts that will be subject to wear and tear (i.e. bearings, impeller). These are the parts you need at the worst possible time – right in the middle of the job. They are the job stoppers. If you are not sure which items would be best to keep on hand, speak with your operators or mechanics or call the manufacturer and have them give you a list.

Now let’s take a look at the second question. This is as important as having the parts in the first place. You planned ahead and stocked key parts, but when the time comes and you need them, you can’t remember where they are. The best thing to do is to develop an inventory system for storing these parts and make sure that key people are aware of the system.

You are not working your tail off to lose money or even to break even; you started your business to make money. I know most of us think we don’t need these parts because we’ll change them out before needed and they won’t go out on you. The reality is that a majority of people are just too busy and changing them out slips through. Take a moment and consider the real cost of not stocking your critical replacement parts.

Need information about replacement parts for your Crisafulli product?

Whether you have just installed your new dredge or you have been dredging for a while, you should follow a lubrication and maintenance schedule in...

Submitted by Dave Stoltenberg, Dredge Rental Specialist, SRS Crisafulli

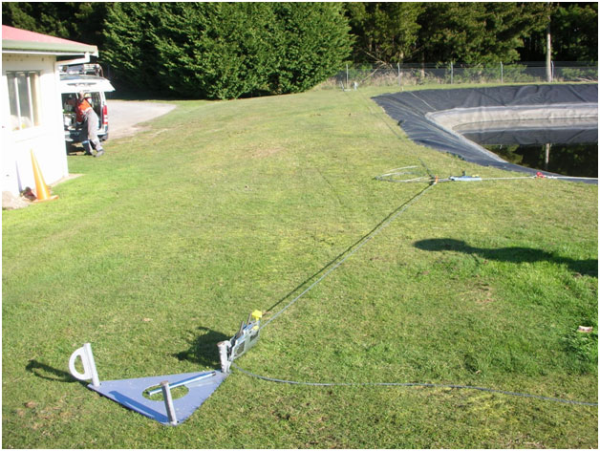

The propulsion and traverse systems are critically important to the operation of an unmanned, cabled dredge. The FLUMP, SRS Crisafulli's unmanned...