SRS Crisafulli Asks "What is Coagulation and Flocculation?"

By Laura M. Fleming, SRS Crisafulli President/CFO

2 min read

Laura Fleming : Tue, May 28, 2013 @ 13:05 PM

What should you do when your town is under multiple and ongoing consent orders for violations of its Montana Pollutant Discharge Elimination System (MPDES) wastewater discharge permit?

By Laura Fleming, President

Excessive lagoon sludge accumulation contributes to the poor performance of any treatment system, particularly in winter. Removing sludge from the lagoon cells will improve treatment at the facility and help to address some of the violations in the Department of Environmental Quality (DEQ) enforcement action.

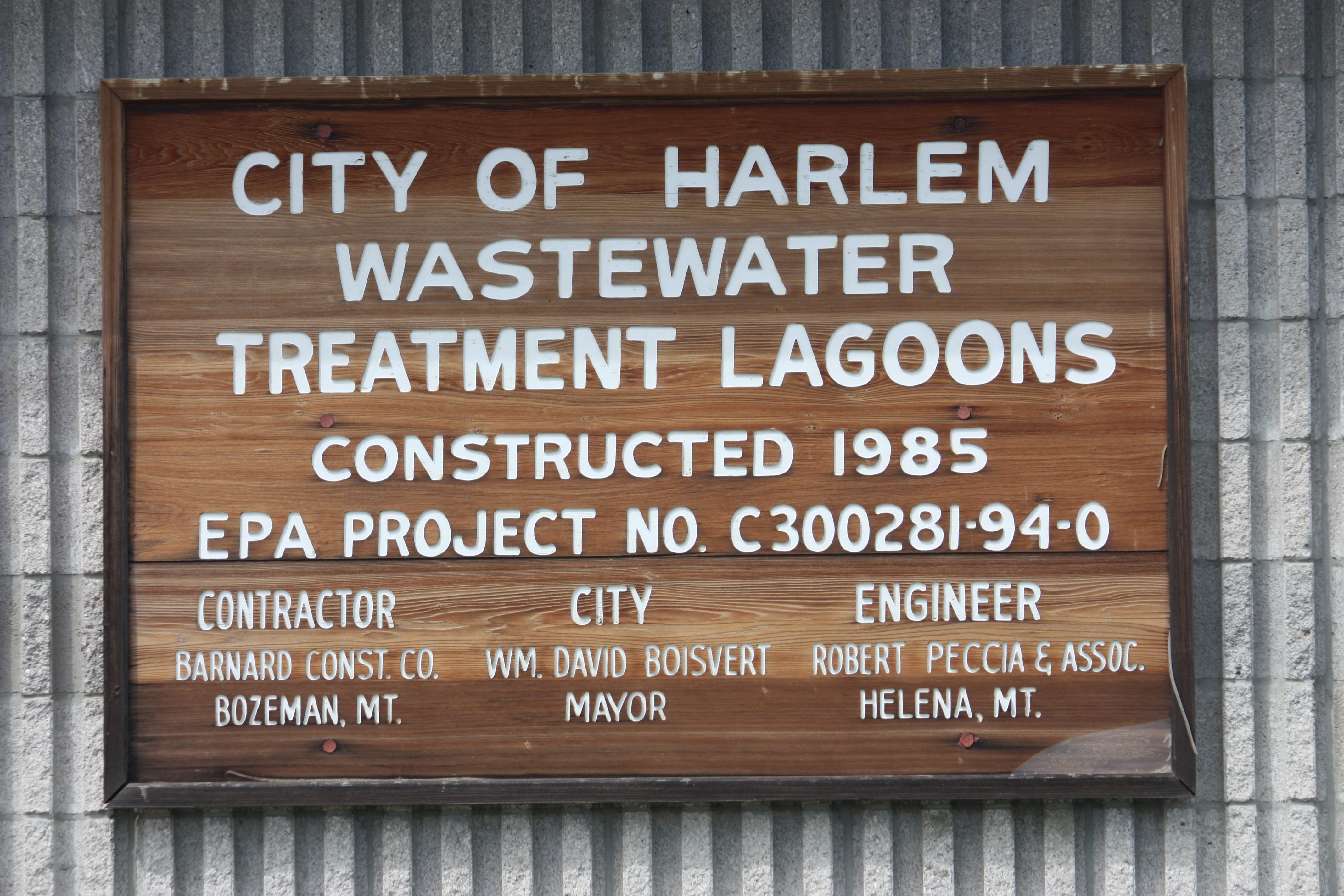

The City of Harlem, Montana has a wastewater treatment system consisting of a three cell partially mixed aerated lagoon system constructed in 1985. The lagoon system discharges to the Milk River under wastewater discharge permit MT0021270. The sludge removal project is the initial step in a comprehensive facility upgrade for the City of Harlem.

Photo: Plaque at the Harlem WasteWater Lagoons: Construction 1985.

Stahly Engineering & Associates, Bozeman, MT and City of Harlem staff conducted a lagoon survey in December 2009. Each cell was sampled in multiple locations using a sludge judge probe assembly operated from a small boat. Solids volumes were calculated using the lagoon bottom area multiplied by the sludge depth. A volume allowance was added for solids accumulated along the sloped sides. The aerated ponds contain significant quantities of settled solids 1 to 2 percent in concentration and occupy between 27 and 58 percent of available volume.

Photo: Aeration in Cell #3, City of Harlem, WWTP, May 2013

Jim Bridges, a Geotube distributor doing business as Clearwater Dewatering, in Nampa, Idaho, brought together a number of parties to collaborate on the City of Harlem’s Sludge Removal Project and turn it into a training opportunity.

WaterSolve, LLC, a national leader in dewatering operations located in Caledonia, Michigan, and a master distributor of TenCate GeoTube® products bid the project. The project is financed by a grant from the Renewable Resource Grant and Loan (RRGL) program of Montana’s Department of Natural Resources.

A subcontractor to WaterSolve, SRS Crisafulli, Inc., Glendive, MT, a manufacturer of sludge removal dredge systems, will be providing the dredge, float line, and operator/trainers to this two week project, located 270 miles northwest of the Glendive factory, just the other side of the Charles M. Russell National Wildlife Refuge.

Montana Rural Water System’s Dan Kramer has qualified a training program, Sludge Removal for Small System Wastewater Operators Workshop, as a Continuing Education Credit (.35 CEC's)for Montana Certified Operators, approved by the Montana DEQ. He is offering training at the jobsite with presentations at City Hall. The training will be offered on Thursday, June 6th, 2013. Training is geared towards small and medium sized wastewater systems. The training will provide information about the importance of the Notice of Intent, daily monitoring of equipment calibration and operation, a discussion of sludge removal, and the on-site demonstration of the working sludge removal system.

Photo: Montana Water Environment Association Award to the City of Harlem for the Outstanding Operation, Maintenance and Administration of a WasteWater Treatment System, 1995. On the wall at the Harlem City Hall.

***

Presentations at this one-day seminar will be conducted by Dan Kramer, Wastewater Technician, and Randy Wilcox, P.E., Technical Sales Manager of WaterSolve. Representative Alan Junker from Tencate, and Ryan Rittall of Stahly Engineering will participate in a roundtable discussion. This program is open to all wastewater operators and is eligible for 0.35 CEC’s. The seminar will cover the problems facing many wastewater treatment lagoon facilities.

This specific project involves the removing of approximately 75 tons (dry weight basis) of lagoon solids from up to three treatment lagoons and pumping to a gravity dewatering system consisting of polymer addition and gravity dewatering bags. All systems are designed by the contractor and all dewatering bags will be left on site.

By Laura M. Fleming, SRS Crisafulli President/CFO

By Laura Fleming, President

SRS Crisafulli, Inc. was chosen in January 2017 as the dredging supplier for a multi-million-dollar renovation to the water treatment plant oxidation...