SRS Crisafulli Explores Dredging and Hydropower

Energy production and consumption worldwide is influenced by many factors. Resource availability, economic activity, population growth and...

2 min read

Elizabeth Kaiser : Wed, Oct 19, 2011 @ 08:10 AM

By Isaiah Helm, Applications Engineer, SRS Crisafulli

If public works departments had a list of fun things to do, dredging sediment out of holding ponds would not be on it. It’s like cleaning the shower in your bathroom. Whether you make it a frequent quick job or an occasional laborious task, time and effort must be set aside to maintain a fixture that is as critical as it is uninteresting. This is the scenario that played out for Georgia’s Cobb County-Marietta Water Authority (CCMWA) during the summer and fall of 2010, as reported in Public Works Magazine.

CCMWA had two water treatment plants and a 25 million gallon reservoir in need of upgrade to meet the EPA’s Stage 2 Disinfectant and Disinfection Byproduct Rule of 2006. During the upgrade, one plant would be running, one shut down. The reservoir had to be at full capacity to do this. Unfortunately, it hadn’t been dredged since 1978 and was half full of sludge.

The reservoir was restored to its original 14-foot depth

The reservoir was restored to its original 14-foot depthTiming of all the different upgrade stages coupled with the EPA deadline meant the reservoir had to be cleaned out in six months. (The dredging had originally been scheduled to take place 2013-2014.)

In other words, the CCMWA had to make up over 30 years of maintenance in 6 months (that would be one nasty shower!). The result: increased scale, decreased competition, and ultimately an increased cost. The amount of dewatering equipment doubled. Four mobile belt presses and four recessed chamber presses were used. Fifty trucks made four 45-mile round trips per day. Bidding on the project was limited to the few large contractors who were even capable of completing the project. There were five bidders and all five of them listed the same two companies as their subcontractors. Total cost to dredge the reservoir and perform maintenance on the banks and sluice gates totaled just over $4 million.

The World Dredging Mining & Construction Journal [1] contains a version of the article authored by Steve Gibbs. It goes on to discuss some observations from the project:

One of the lessons learned by CCMWA is the need for regular dredging of the reservoir. One benefit of regular dredging is economics – greater capacity in the reservoir reduces the amount of pumping necessary to bring water from the Chattahoochee, thus saving electrical costs. Also, doing a smaller dredging project every five years or so will eliminate the need to do a massive project such as the one just completed.

A deeper, cleaner reservoir will allow suspended solids to settle out better, which will enhance treatment efficiency. The reservoir will also have ample capacity while the treatment plants are in their construction phase.

“This (the reservoir dredging project) will decrease the potential for water quality problems or process issues at our treatment plants,” said Ginn (CCMWA process engineer). “It’s a very good proactive preventive maintenance step.”

There you have it. Proactive dredging of sludge-collecting ponds really does make life easier in the end. It also increases the options:

Put out a request for bids on that smaller dredging project every five years

Contract with a dredging company to clean out the pond every five years

Rent dredging and dewatering equipment directly and eliminate the middleman

Purchase an automated or remote dredging and dewatering system and have it permanently installed for complete self-sufficiency

At least it’s something to think about while you’re cleaning your shower tonight.

[1] World Dredging Mining & Construction Journal, “Proper Planning for a Perfect Project” (Volume 46, Nos. 11/12, Page 16)

Do you have a proactive dredging project in mind? Fill out our dredge application form.

Need some advice? Request a free consultation.

Would you like to receive our monthly newsletter? Sign me up!

Energy production and consumption worldwide is influenced by many factors. Resource availability, economic activity, population growth and...

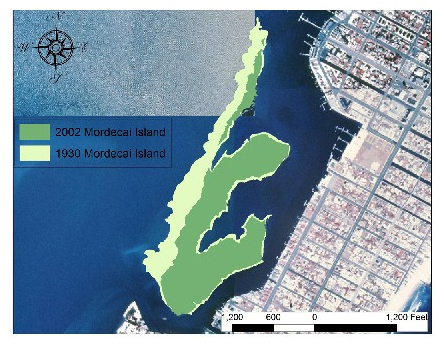

Many situations can complicate a shoreline’s integrity. These can range from flooding, hurricanes and man-made disasters and can even include aquatic...

The Rotomite-6000-C, SRS Crisafulli’s newest self-propelled dredge, broadens the Rotomite-6000’s capabilities to include removal of highly abrasive...