Crisafulli Dredges

Crisafulli manufactures eight standard hydraulic dredge models - four models of the portable self-propelled Rotomites (Rotomite-6000, Rotomite-6000 CD, Rotomite-6000 CE, and Rotomite SD110), and four models of its portable remote controlled, automated electric powered FLUMP (floating lagoon pumper) series (3-inch stand duty, 3-inch severe duty, and 4-inch severe duty), and the diesel powered FLUMP, the RDF. Crisafulli will custom engineer each of its standard models to meet customers' specifications.

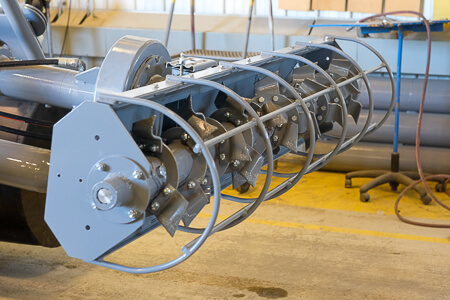

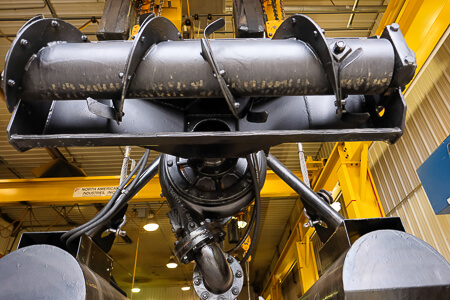

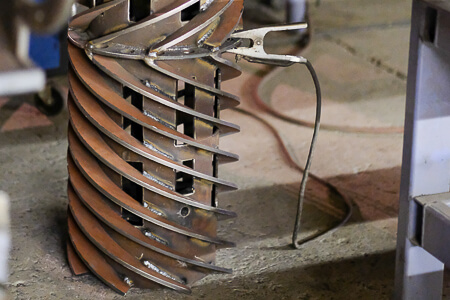

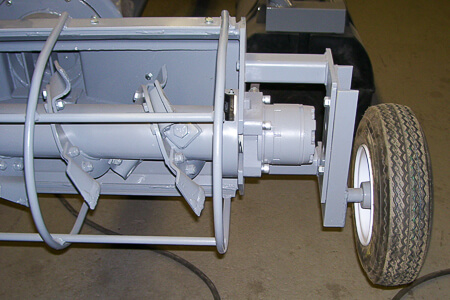

Crisafulli dredges use horizontal augers. Rotomites are self-propelled and steerable and operate without expensive support vessels. FLUMP dredges operate in a cabled environment, are remote controlled, and can be partially or fully automated.

Customers use our equipment to dredge biosolids and residuals from municipal water and wastewater lagoons; dredge industrial lagoons of waste, mine tailings, sediment, or slurries; remove settled solids from ponds or lagoons without draining the ponds or taking ponds out of service; implement or manage conservation projects, including maintenance of small ponds.

.jpg?width=1200&height=800&name=1200w-pivotflumpnd%20(2).jpg)

4" 50HP Flump

Remote Electric Dredge

| Maximum Dredging Depth: | 12' |

| GPM: | 800 |

| Cubic Yards Per Hour: | 40 |

| Weight: | 6000 lbs |

RDF-50

Remote Diesel Dredge

| Maximum Dredging Depth: | 15' |

| GPM: | 800 |

| Cubic Yards Per Hour: | 45 |

| Weight: | 8500 lbs |

Rotomite SD-110

Manned Diesel Dredge

| Maximum Dredging Depth: | 12' |

| GPM: | 1400 |

| Cubic Yards Per Hour: | 80 |

| Weight: | 9000 lbs |

Rotomite 4000

Manned Diesel Dredge

| Maximum Dredging Depth: | 12' |

| GPM: | 1400 |

| Cubic Yards Per Hour: | 80 |

| Weight: | 13000 lbs |

Rotomite 6000

Manned Diesel Dredge

| Maximum Dredging Depth: | 20' |

| GPM: | 2000 |

| Cubic Yards Per Hour: | 150 |

| Weight: | 18000 lbs |

Rotomite 6000CD

Manned Diesel Dredge

| Maximum Dredging Depth: | 20' |

| GPM: | 2000 |

| Cubic Yards Per Hour: | 200 |

| Weight: | 30000 lbs |

Made in Montana

60 years of experience building pumps. Crisafulli has engineered and built pumps for more than 60 years and started business as Crisafulli Pump Company. Crisafulli pumps are proven reliable and effective. Crisafulli builds pumps in sizes ranging from 2 inch (the diameter of the discharge pipe on the pump) to 24 inches.

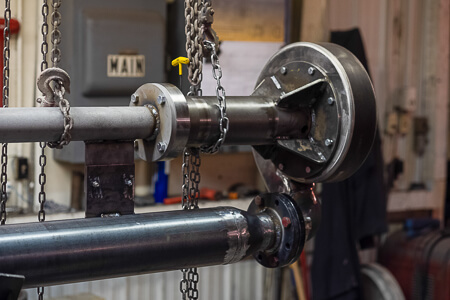

Rugged construction. The Crisafulli pumps used on the FLUMP and the Rotomite are American made in Glendive, Montana, manufactured with an ASTM AR400 mild carbon steel (BHN 400 hardness) pump volute and impeller, dual carbon/ceramic shaft seals. The pump is mounted directly behind the cutterhead and is lowered into the pond on the dredge's ladder.

Floating DIscharge

To carry the dredged sludge from the FLUMP or Rotomite to the designated disposal site, typically on land, the FLUMP uses a Crisafulli Integral Floating Discharge Line. The Discharge Line is modular, offered in either 15 foot or 20 foot rigid lengths, and 5 foot flexible lengths, and is one of two styles: aluminum pipe with foam floats; and polyethylene pipe with foam floats.

The Crisafulli Floating Discharge Line system is highly versatile, easy to set up and use, and can carry heavy, concentrated sludge across a pond to the discharge site, distances often up to 500 feet or substantially farther.

.jpg?width=450&height=300&name=450w-SpurLinerProtection%20(2).jpg)