| SD-110 | Rotomite 4000 | Rotomite 6000 | Rotomite 6000CD | |

|---|---|---|---|---|

| Maximum Dredging Depth: | ||||

| Cutterhead Width: | ||||

| Weight: | ||||

| Dredge Length: | ||||

| Dredge Width: | ||||

| Dredge Height: | ||||

| Draft: | ||||

| Pontoon Material | ||||

| Horse Power: | ||||

| GPM: Gallons Per Minute of water the dredge can pump. |

||||

| Cubic Yards Per Hour: Estimate of solids production. The unique material being pumped means no job site will yield the same result. |

||||

| Operator on Board: | ||||

| Cab: | ||||

| Cabled Traverse: | ||||

| Self Propelled: |

Rotomite Dredges

Self-Propelled Diesel Dredges

Crisafulli manufactures four standard hydraulic Rotomite dredge models - Rotomite 6000, Rotomite 6000 CD, Rotomite SD-110, and Rotomite 4000. Crisafulli will custom engineer each of its standard models to meet customers' specifications.

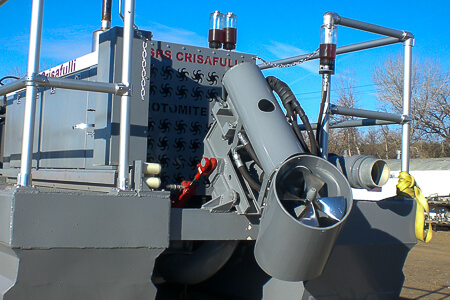

Crisafulli dredges use horizontal augers. Rotomites are self-propelled and steerable and operate without expensive support vessels.

Customers use our equipment to dredge biosolids and residuals from municipal water and wastewater lagoons; dredge industrial lagoons of waste, mine tailings, sediment, or slurries; remove settled solids from ponds or lagoons without draining the ponds or taking ponds out of service; implement or manage conservation projects, including maintenance of small ponds.

The SD-110 is Crisafulli's lightest self propelled dredge. The hydraulic thruster allows the SD-110 to dredge irregular shaped ponds, and maneuver into boat slips, and other tight locations.

Portability. Weighting only 9,000 lbs, with an aluminum super structure, the SD-110 measures only 25 x 8.5 feet, can be lifted by almost any crane, and is transportable anywhere in the US without special permitting on a regular deck-over trailer. Custom trailers are available for easier installation and removal of the dredge on sites with boat ramps.

Easy to operate. Designed with the operator in mind, the dredge has on-board storage in the operator’s station and a 12 VDC power point for the operator’s personal items - i. e., cell phone, and an adjustable helm.

Key Benefits of Rotomite SD-110 Ownership

- Light Weight

- Self Propelled

- Sophisticated instrumentation options measure dredging performance.

- High solids dredging performance with minimum turbidity

- Easily transported to multiple sites

- Simple to maintain

- Reliable and manufactured to last

- Superior after-sale support from Crisafulli worldwide

The Rotomite 4000 has the same pump, engine, and hydraulics as the SD-110, but it's built with steel pontoons, and has a maximum dredge depth of 15'. The Rotomite 4000 is a good solution when the strength of steel is required due to frequent moves, but the production of the SD-110 is sufficient.

The Rotomite 6000 is Crisafulli's full feature dredge.

Great visibility. The Operator has a clear view of dredging operations from the forward positioned cab with large windows on all four sides. The cab with A/C and heat is accessible from either side of the dredge for improved convenience, productivity, and safety.

The operator can articulate the cutterhead to keep the cutting teeth at right angles to the face of the dredged material. Coupled with the hydraulically powered ladder, which uses the dredges weight, our dredge can break up settled solids, and dig down if required.

The hydraulic thruster on the Rotomite 6000 generates 1,000 lbs of thrust, which allows the dredge to handle most applications. For tougher material, the Rotomite 6000 has a cable traverse system, which genreates 4,000 lbs of thrust, using a tenth of the horse power.

Key Benefits of Rotomite 6000 Ownership

- Powered by a diesel John Deere engine, with service centers worldwide

- Sophisticated instrumentation options measure dredging performance

- High solids dredging performance with minimum turbidity

- Easily transported to multiple sites

- Comfortable cab, with optional sound system

- Reliable and manufactured to last

- Superior after-sale support from Crisafulli worldwide

Crisafulli’s all-purpose Rotomite 6000 CD dredge, powered by a 275 Continuous Horsepower diesel engine, is engineered for a full range of dredging applications from soft to highly abrasive material and slurries, including sand and gravel. Incorporating many design features from the successful Rotomite 6000, the Rotomite 6000 CD achieves very high productivity, coupled with relatively low cost resulting in an rapid ROI (Return On Investment). The Rotomite-6000 CD is designed for customer convenience and safety, with a forward mounted heated & air-conditioned operator’s cab with 360-degree visibility, and a safety guardrail surrounding the dredge.

Key Benefits of Rotomite 6000 CD Ownership

- Able to dredge abrasive materials, like sand

- Cast Pump

- Powered by a diesel John Deere engine, with service centers worldwide

- Sophisticated instrumentation options measure dredging performance

- High solids dredging performance with minimum turbidity

- Easily transported to multiple sites

- Reliable and manufactured to last

- Superior after-sale support from Crisafulli worldwide

Propulsion

Hydraulic Thruster

Crisafulli's hydraulically powered propulsion and steering system for the Rotomites is unique in the dredge world. Providing both thrust and steering, the System provides adequate force to enable the horizontal auger on the cutterhead to engage, cut, and dislodge compacted solids.

Unlike propulsion systems on many competitors' dredges, that either crawl along the lagoon bottom thereby generating substantial turbidity, or drive one or more "spuds" into the lagoon bottom that must be removed and the dredge relocated repeatedly by a support vessel during the dredging process, the Crisafulli propulsion system generates little or no turbidity and enables the Rotomite to be self-sufficient and move easily around the lagoon, canal, or river without external support. The System provides both forward and reverse thrust. Rotomite propulsion systems are more flexible and versatile enabling Rotomites to be more productive and less costly to operate.

.jpg?width=450&height=300&name=450w-SD110Lake%20(2).jpg)

.jpg?width=450&height=300&name=450w-SpurSD110Photos%20(7).jpg)