Crisafulli Pumps

Humpback Trailer Pump

Rugged, reliable, versatile Crisafulli Trailer Pumps move millions of gallons of water at locations around the world. Crisafulli Trailer Pumps are offered as PTO Powered or as Self-Powered. Crisafulli PTO powered Trailer Pumps are driven from the power take-off (PTO) fitting on any tractor, and are offered as 540 RPM (revolutions per minute) models or 1,000 RPM models.

Crisafulli Self-Powered Trailer Pumps are powered by electric motors, or gas, diesel, or propane fueled engines mounted on the pump frame, or by a Crisafulli Power Unit. Crisafulli offers PTO powered trailer pumps in four models - Humpback™, Short Hitch, Three Point Hitch, and PTO Slurry Pumps, with a wide range of pump sizes, flows, and head capacities (ranging up to 18,000 gallons per minute and more than 50 feet of head) for each model.

.jpg)

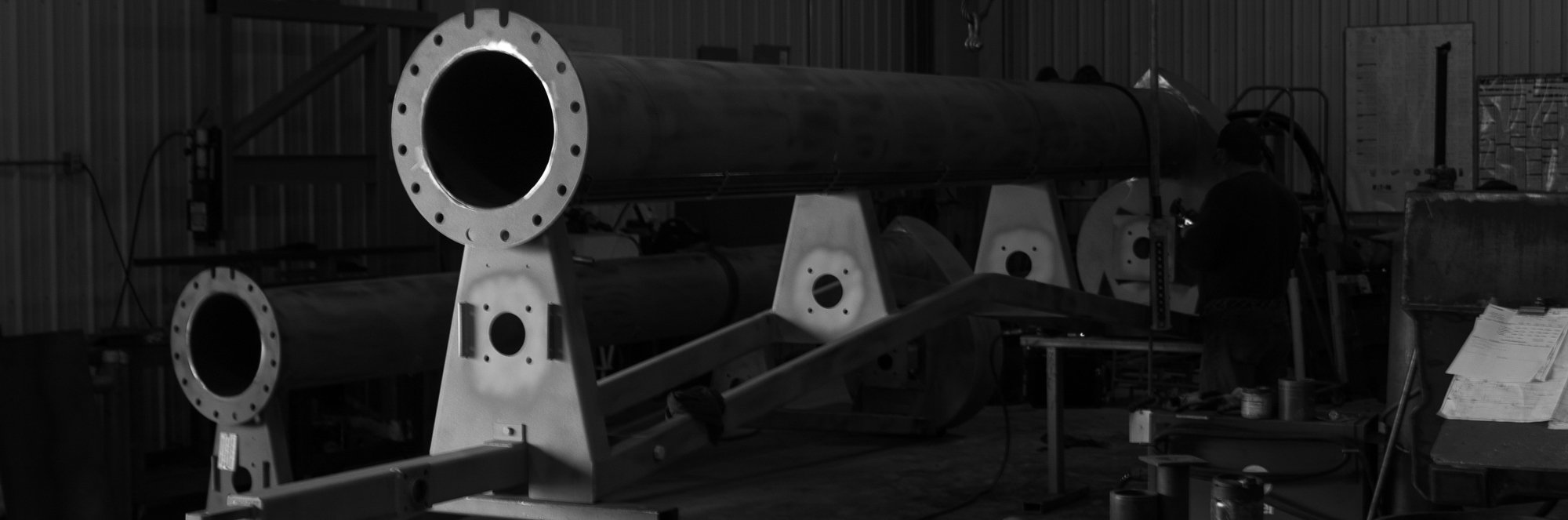

Vertical Pump

Crisafulli Vertical Pumps are dependable, powerful, and versatile. They are designed for stationary applications, such as sewage digesters and lift stations, manure tanks, chemical sumps, and dry docks.

Standard Duty Crisafulli vertical pumps are reliable, proven performers. They are equipped with grease lubricated, sealed bearings and are an ideal choice for moving relatively clean water. For sand, silt, mud, sludge or abrasives, choose the rugged Severe Duty version, which are constructed with abrasion-resistant heat treated steel (450 Brinell hardness), have dual mechanical shaft seals (to prevent contamination), and an enclosed oil filled bearing frame, allowing the pump to perform in the most demanding environments.

Steel construction assures long life and trouble free operation. The pumps pass remarkably large solids and pump high-weight/high viscosity fluids with ease.

.jpg)

Slurry Pump

Agitate, mix and pump most viscous or solidified sludges from industrial, municipal and agricultural waste lagoons with a SRS Crisafulli slurry pump. The pumps also work well for refineries, municipalities and geothermal plants.

Productivity

An operator can slurry and clean a 200 X 200 foot 8-foot deep pond in 6 hours with a Crisafulli slurry pump. Mixing rates up to 10,000 gallons per minute. Pumping rates up to 9,000 gallons per minute.

Operation of the Slurry Pump. Crisafulli has engineered its Slurry Pump with a "Slurry Gate" which the operator opens to agitate, mix, and slurry the pond. The submersible centrifugal pump draws solids and liquids into the pump, blends and discharges the material through the slurry gate. The operator closes the slurry gate hydraulically and pumps the material at high volume out of the lagoon to a receiving tank, receiving vehicle or to another lagoon.

No separate agitator or mixer pumps are needed.

.jpg)

3 Point Hitch Pump

Designed to pump from steeply banked ponds, lakes, and canals Crisafulli Standard Industrial Duty Three-Point-Hitch Humpback Pumps are PTO powered and can pump at a 60 degree angle while keeping your tractor on the level. The HumpbackTM Three-Point-Hitch Pumps volute and impeller are manufactured from 3/8" A36 mild carbon steel. The volute and impeller are mounted on a 14' long, rigid pump frame with anti-friction ball bearings (five on double suction pumps), telescopic PTO shaft, three-point-hitch connection and a short discharge pipe with an oval band to adapt to CrisafulliTM discharge tubing. Impellers for 4", 6", and 8" models are single suction; for larger models (10", 12", and 16") the impellers are double suction.

Short Hitch Trailer Pump

Crisafulli Standard Industrial Duty Short Hitch Trailer Pumps volute and impeller are manufactured from 3/8" A36 mild carbon steel. The volute and impeller are mounted on a 15' long, single axle trailer with a heavy duty driveshaft supported by four sealed, anti-friction ball bearings (five on double suction pumps), with remote grease lines extended to the front of the pump, telescopic PTO shaft, pin-type hitch, trailer jack and an 11' long discharge pipe with an oval band to adapt to Crisafulli discharge tubing. The pumps are available with 3/8" thick industrial duty pump volute and impeller parts. Standard Duty models are powered by tractors whose PTO shafts turn at 540 RPM.

Pump Curves

-

16" Pumps

Regular Lift - 9,000 GPM, 75 HP

High Lift - 10,000 GPM, 150 HP

-

12" Pumps

-

10" Pumps

-

1000 RPM Curves

8" KX Series - 4,000 GPM, 115HP

12" KX Seriess - 7,500 GPM, 145 HP

16" KX Series Regular Lift - 9,500 GPM, 170 HP

16" KX Series High Lift - 11,000 GPM, 225 HP

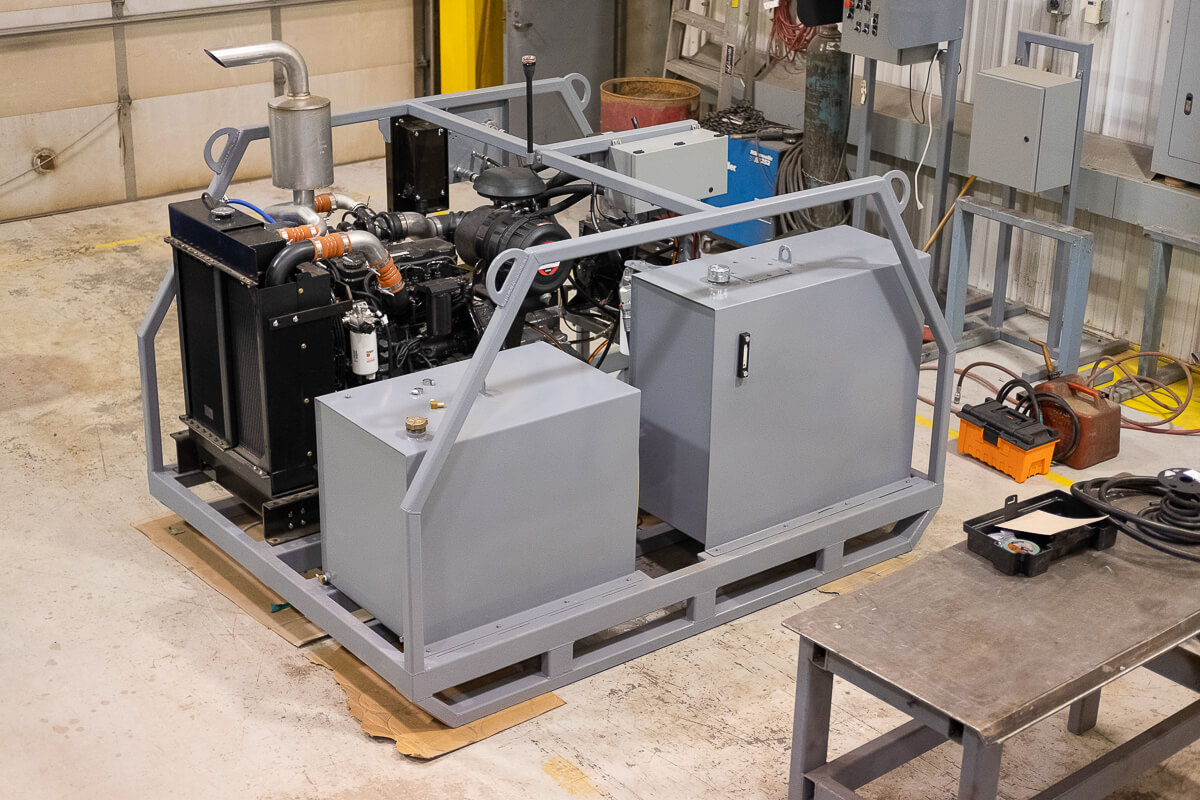

Power Units

Crisafulli skid mounted and trailer mounted power units, powered by electric motors or diesel engines, that have PTO take offs or hydraulic systems. To provide hydraulic power to Crisafulli Hydraulic Pumps, Crisafulli builds Crisafulli Standard Power Units in four configurations, each either skid or dual axle mounted - i.e., Crisafulli Diesel/Hydraulic Power Units, Crisafulli Gas/Hydraulic Power Units, Crisafulli Electric/Hydraulic Power Units, or Crisafulli PTO/Hydraulic Power Units. Depending on the model, hydraulic output ranges from 15 GPM to 150 GPM. Crisafulli will build your power unit mounted on a skid or a trailer for ease in transporting from site-to-site. The control panel on a Crisafulli Power Unit will be designed for your specific application.

Submersible Pumps

Crisafulli Submersible Pumps come in all shapes and sizes. They can be powered hydraulically, or electrically. We build them to your requirements.

There are many ways to customize your pump, to your specific application. Our submersible pumps can be built with a slurry gate, or with screens, or choppers. If your application is unique, contact our sales engineers and we'll help find the right solution.

Our most common submersible pumps are built with S or J series pumps, but if you require more flow, we can build yours with an L series pump.

Floating Pumps

Crisafulli designs and manufactures custom, multi-purpose, floating platforms. Crisafulli offers floating solutions to a variety of industrial, municipal, and private firms which require reliable, efficient means of supporting floating pumps, for maintenance platforms and recreational docks.

Our floating platforms can be used to float any size Crisafulli Pump, or any other pump brand. The platforms can also be built as maintenance work platforms, for machinery support, or recreational docks.

Contact our sales engineers to learn more.

Features and Benefits

- A choice of unique impeller designs gives you more flexibility; the closed impeller moves a high volume of water, while the open impeller can handle slurries, trash, dirt, and solids.

- Crisafulli Trailer Pumps are fabricated and customized specifically to your needs. While there are higher efficiency pumps out there for clean water, they often can't handle the variety of materials Crisafulli Pumps can handle. When the water is dirty, you can count on a Crisafulli Pump to handle the grit without seizing.

- If you don't want to use the power take-off on your tractor or other equipment for your trailer pumps, add a Crisafulli Power Unit. Put power right on the pump frame; choose diesel, electric, gas or LP fuel. Or put a trailer or skid mounted Crisafulli Power Unit to work alongside your Crisafulli Trailer Pump.

- Because Crisafulli Pumps come in a variety of configurations, you'll always find a match for your needs.

- Add a slurry gate to make your pump a powerful mixer. Open the gate to mix, then close it to pump away the slurry.

- Steel construction. Crisafulli Trailer pumps are built from 3/8" (industrial) mild carbon steel for durability and strength.

- Crisafulli Trailer Pumps are built on single axle trailers with heavy duty drive shafts which enable you to move your trailer pump from site to site easily and safely.

- Sealed or waterlube bearings - Crisafulli Trailer Pumps are custom-designed to match the kind of material you pump.

- Crisafulli offers a full range of options to match your volume needs with discharge sizes from 4" to 24".

- Crisafulli Trailer Pump speed is matched to your PTO - 540 RPM is standard, but we also offer 1,000 RPM.

- Each Crisafulli Trailer Pump has a Crisafulli Impeller Inside - your assurance of quality, performance, reliability and long useful life

.jpg?width=450&height=300&name=450w-Custom%20EoF%20with%20screens%20on%20intake%20(1).jpg)

Custom Pumps

If you have a unique pumping challenge, please give us a call, and we'll work with you to build the right solution to your problem.

.jpg?width=1200&height=800&name=1200w-SpurTrailerPumpPhots%20(1).jpg)

.jpg?width=1200&height=800&name=1200w-slurry%20gate%20and%20spray%20nozel%20pump%20(1).jpg)

.jpg?width=1200&height=800&name=1200w-electricskidmountedpto%20(2).jpg)

.jpg?width=1200&height=800&name=1200w-diesel%20trailer%20mounted%20pto%20unit%20(1).jpg)